Rubber Track for Caterpillar (CAT) 300.9D (Fit Caterpillar (CAT) 300.9D Excavator)

Basic Info.

- Item Fit: Caterpillar (CAT) 300.9D

- Item Condition: New

- Item Weight: 65 lbs

- Item Maker: FLundercarriage

- Place of Origin: Quanzhou

Delivery Info.

- Inventory Class: Standing

- Packaging: Carton/Pallet

- ETD: 24-72 Hours

- ETA: 5-30 Days

- Track Size: 180x72x37, an ideal match for compact excavation operations.

- Manufacturing Assurance: Comes standard with a warranty against any manufacturing defects.

- Tread Patterns: Choose from different tread patterns to match your specific work terrain; turf-friendly option available and shipped by default.

- Exact Fit: These tracks are precisely engineered for the Caterpillar® 300.9D and 300.9D VPS models.

- Alternate Part Numbers: Caterpillar Dealer Part Number: 367-4063.

- Durable Material: Manufactured with helically wound continuous steel cords, coated to prevent rust, and made with non-recycled rubber for long-lasting use.

- Advanced Factory Production: Our state-of-the-art factory is dedicated to continual quality improvements, delivering robust, cut-resistant edges and heavy-duty guide systems.

- Non-Marking Tracks: We offer non-marking rubber tracks for sensitive surfaces that require no scuff or streak marks, ideal for indoor job sites.

- Tension Idler: (373-1851) Part dedicated to maintaining proper track tension.

- Bottom Roller: (527-3878) Designed for smooth, reliable rolling performance.

- Rubber Track: (367-4063) The right track to keep your Cat 300.9D running smoothly.

В наличии: 131

Share This Product

Tread Patterns Commonly Available

Flundercarriage Show

Why Choose FL Rubber Track

-

20+ Years Experience

100+ Dealers Globally

300000+ Stock Keeping Units

50000000+ USD Annual Sales

-

Custom Solutions for Old Machines

Professional Design & Service Team

Renowned Replacement Parts Manufacturer from China

Fulian's rubber tracks are engineered for maximum durability and flexibility. Designed to reduce vibration and enhance traction, they ensure smooth operation even on the roughest terrains, making them an ideal choice for your machinery.

Our parts are compatible with a wide range of machinery brands including Bobcat, Caterpillar, Case, Doosan, GEHL, Hitachi, Hyundai, IHI, Kubota, Kobelco, Komatsu, Pel-Job, Takeuchi, Volvo, and many others. Designed to meet OEM specifications, they ensure optimal performance and durability across various equipment models.

Trade Show Events

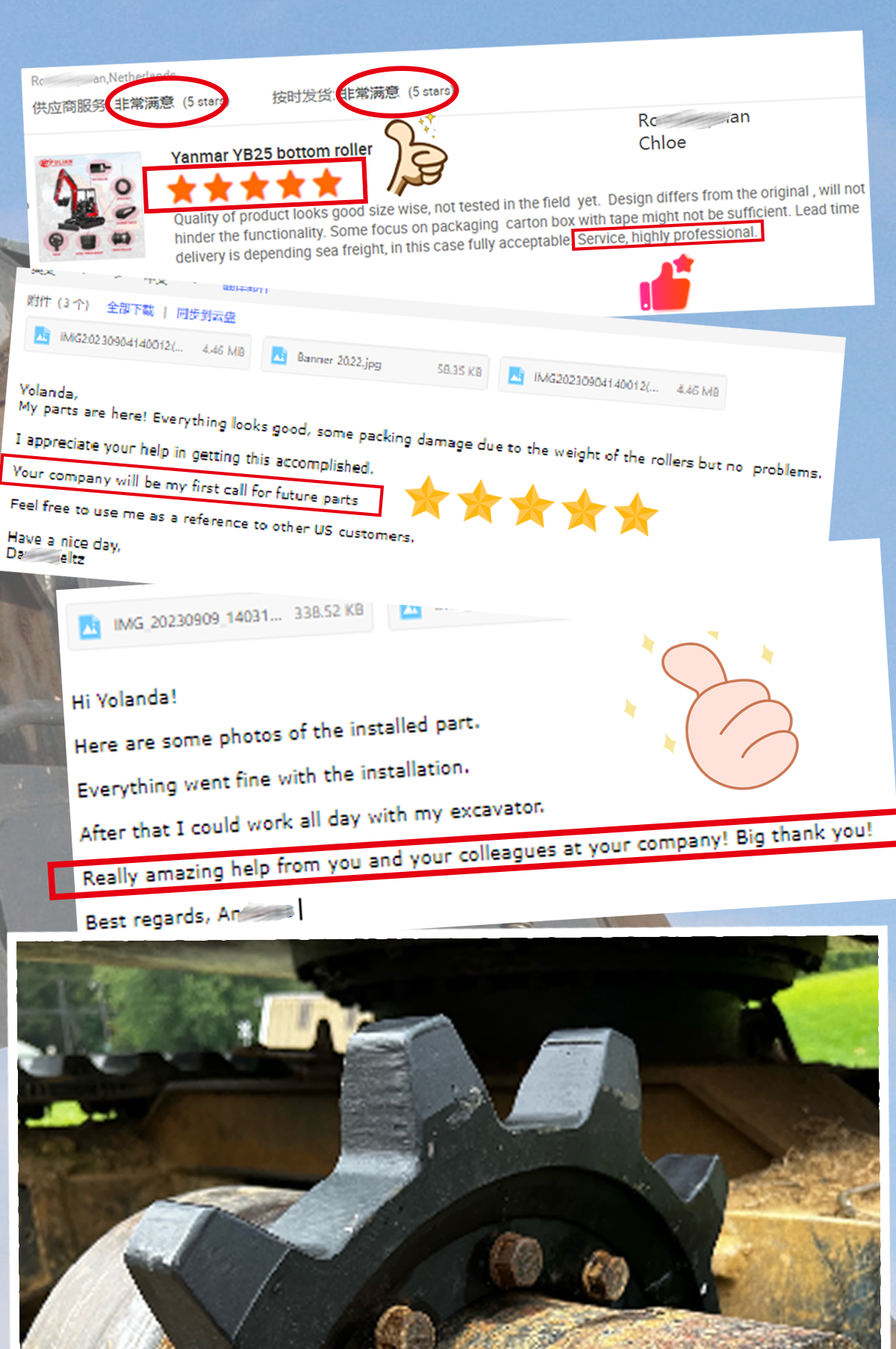

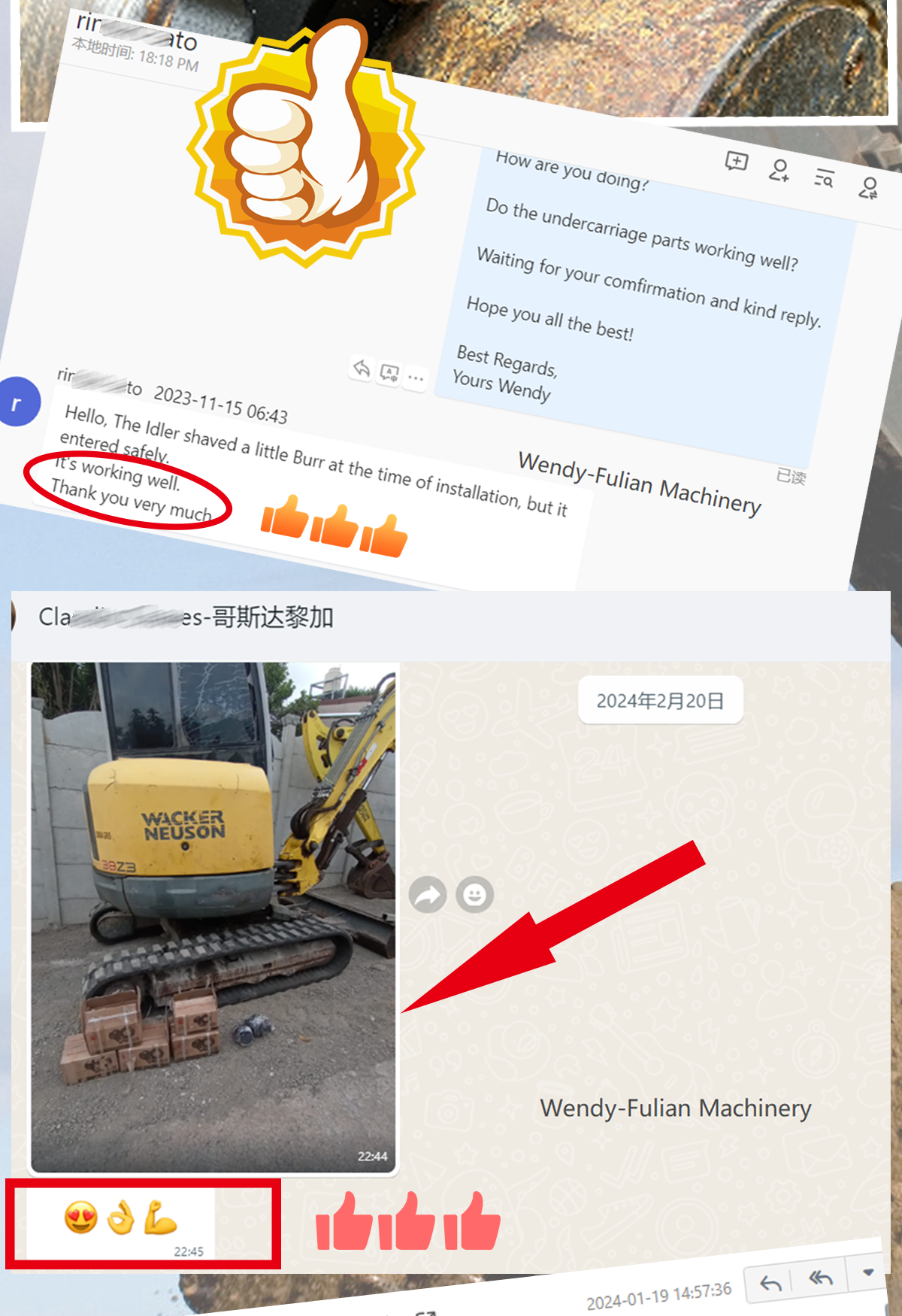

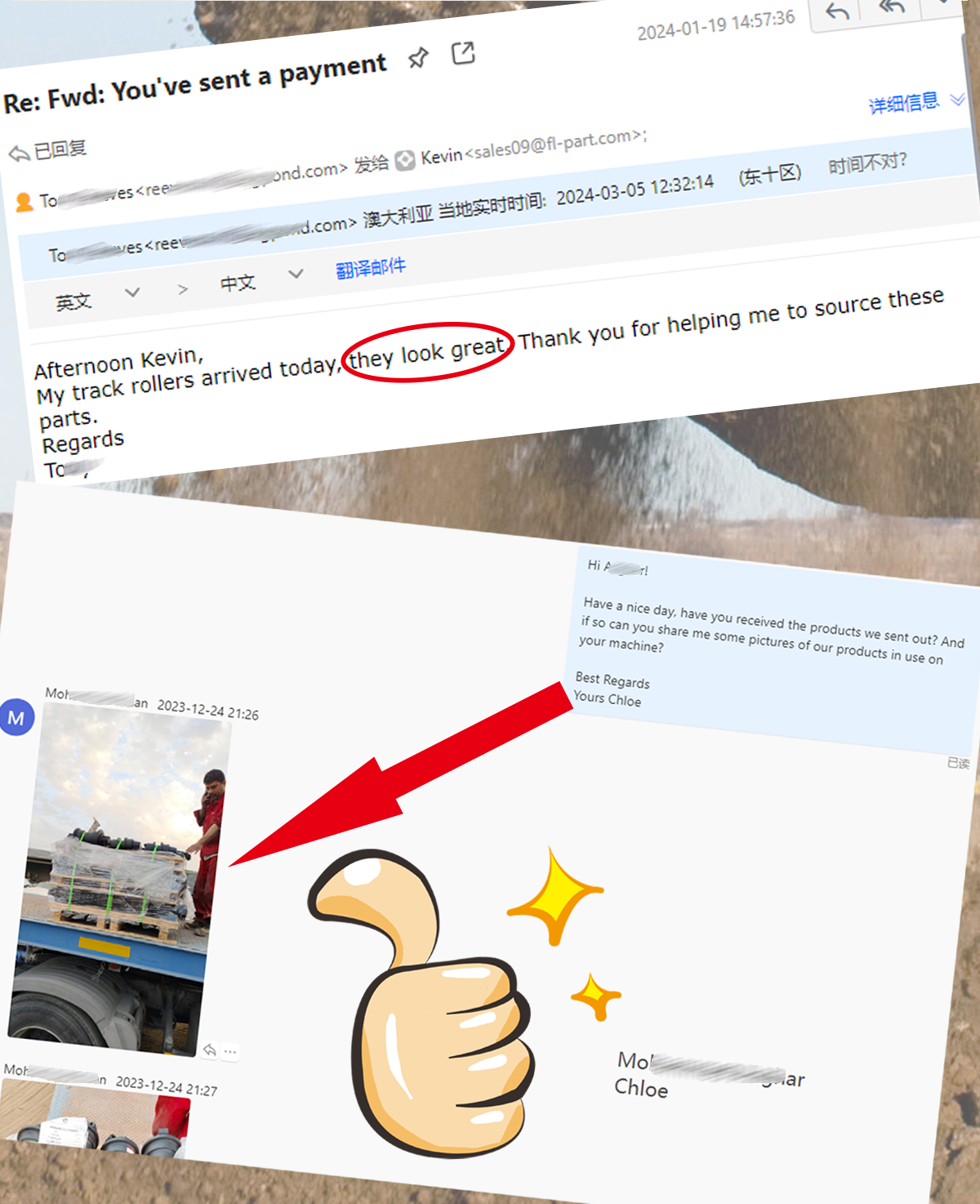

Customer reviews

Fulian Certifications

Packaging & Delivery

FAQ

What is a rubber track?

A rubber track is essentially a round belt made of a blend of rubber and either metal or fiber elements. It functions as a rubber transmission belt that is primarily used in moving systems. Owing to its durability and flexibility, it's a popular choice for agricultural machinery and construction equipment, serving as a viable alternative to traditional metal tracks and tires. The rubber track facilitates smooth transportation and enhances the efficiency of machines across various operational terrains.

Are rubber tracks better than steel?

When not utilized properly, rubber tracks are susceptible to damage from jagged or solid objects on the terrain. Navigating across slick or muddy conditions can prove challenging with rubber tracks. For such environments, a more resilient material like steel is a more suitable choice to ensure optimal performance and reduced wear and tear.

Why does my rubber track keep coming off?

A common cause for the derailment of a rubber track could be attributed to deformations in the track frame. A perfectly aligned and straight frame is paramount for the track's operation. With the passage of time and continual use, the track frame may suffer alterations such as twisting, bending, or incurring other forms of damage, which can impact the track's performance.

What are the benefits of rubber tracks?

Reduced ground impact: By evenly spreading the weight of the machine, rubber tracks minimize the likelihood of it becoming mired in soft ground. Enhanced operator experience: The supple nature of rubber tracks affords a gentler, quiver-free operation, contributing to a more agreeable day for the machine's operator.