Takeuchi TL130 Aftermarket Rubber Track (Fit Takeuchi TL130 TL230 Loader)

Basic Info.

- Item Fit: Takeuchi TL130 TL230

- Item Condition: New

- Item Weight: 350 lbs

- Item Maker: FLundercarriage

- Place of Origin: Quanzhou

Delivery Info.

- Inventory Class: Standing

- Packaging: Carton/Pallet

- ETD: 24-72 Hours

- ETA: 5-30 Days

- Tread Design: The tracks come with a C-Tread pattern, offering excellent traction for a variety of surfaces.

- Track Size: These tracks are 12.5 inches (320 mm) wide and have fifty-two metal guide links for sprocket engagement.

- Compatibility: These rubber tracks are made to replace Bridgestone part numbers 19140-61430 and 19140-99520. They are guaranteed to fit:

- Takeuchi TL 130

- Takeuchi TL 230

- Takeuchi TL 8

- Gehl CTL 65

- Gehl CTL 60

- Mustang MTL 16

- Mustang MTL 316

- Alternate Part Number: The Takeuchi dealer part number for these tracks is 19140-61410.

- Variety: We offer different tread patterns, including an aggressive straight bar track and a popular staggered block tread, for varying job requirements.

- Quality and Durability:

- Our rubber tracks are made with continuous steel cords that are helically wound and coated to prevent rust, ensuring reliable performance in tough conditions.

- We use high-quality, non-recycled rubber in our advanced manufacturing facilities, focusing on continuous product improvement.

- Our tracks are not the cheapest, but we aim to provide the best overall service and value.

- Warranty:

- A standard pro-rated warranty covers manufacturer defects. Additionally, buying sprockets with your tracks extends the warranty by 6 months.

- Changing your sprockets at the same time as your tracks is recommended for optimal performance and lifespan.

- Off-set Block Tread: Ideal for general purpose use, offering good traction and minimal ground damage.

- Off-set C Tread: Provides excellent forward traction and grip, especially useful when operating on slopes.

- Additional Takeuchi TL130 Construction Parts Available:

- Drive Sprocket

- Tensioner Idler

- Bottom Roller

- Front Roller

- Rubber Tracks

94 in stock

Share This Product

Tread Patterns Commonly Available

Flundercarriage Show

Why Choose FL Rubber Track

-

20+ Years Experience

100+ Dealers Globally

300000+ Stock Keeping Units

50000000+ USD Annual Sales

-

Custom Solutions for Old Machines

Professional Design & Service Team

Renowned Replacement Parts Manufacturer from China

Fulian's rubber tracks are engineered for maximum durability and flexibility. Designed to reduce vibration and enhance traction, they ensure smooth operation even on the roughest terrains, making them an ideal choice for your machinery.

Our parts are compatible with a wide range of machinery brands including Bobcat, Caterpillar, Case, Doosan, GEHL, Hitachi, Hyundai, IHI, Kubota, Kobelco, Komatsu, Pel-Job, Takeuchi, Volvo, and many others. Designed to meet OEM specifications, they ensure optimal performance and durability across various equipment models.

Trade Show Events

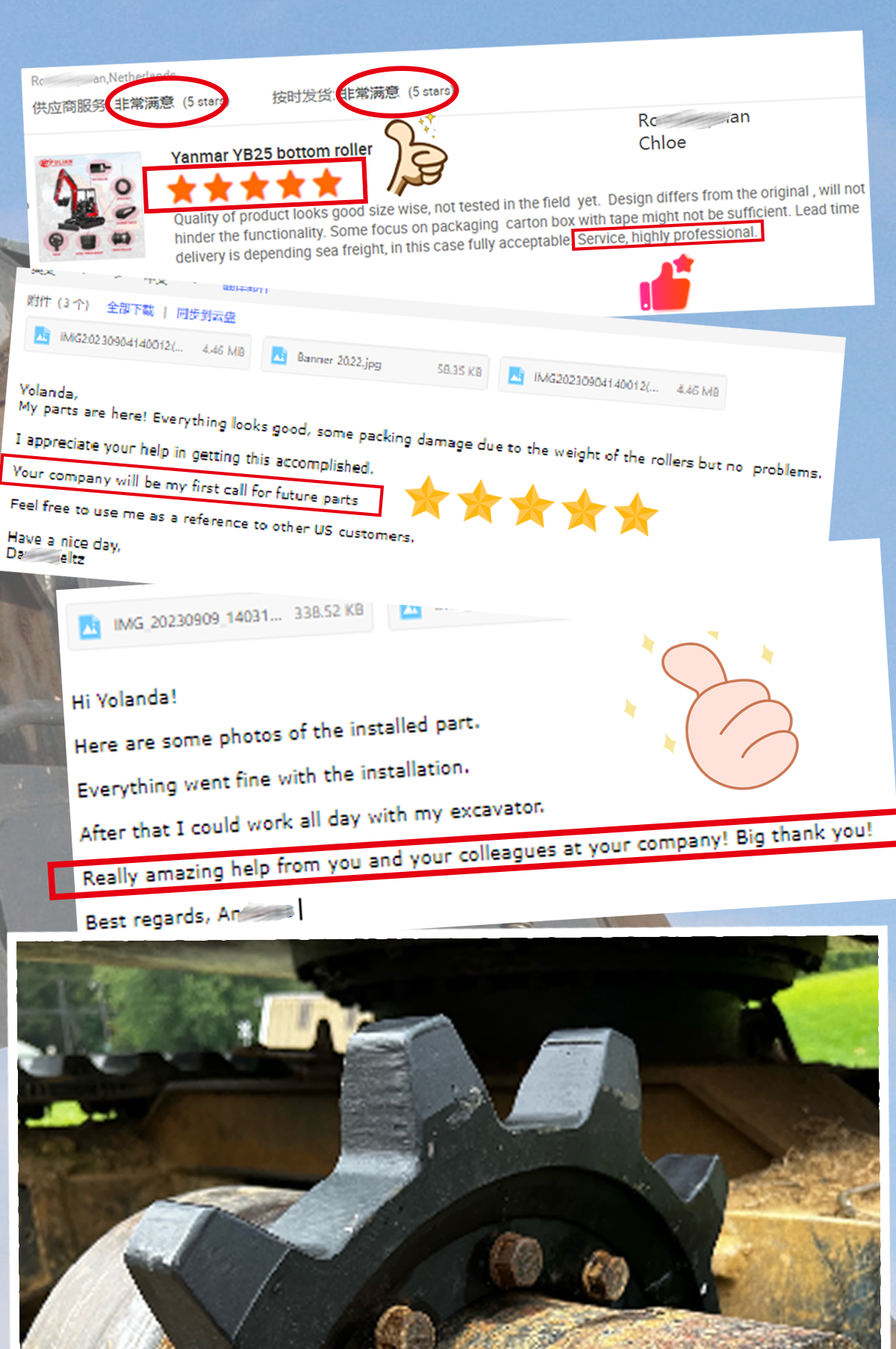

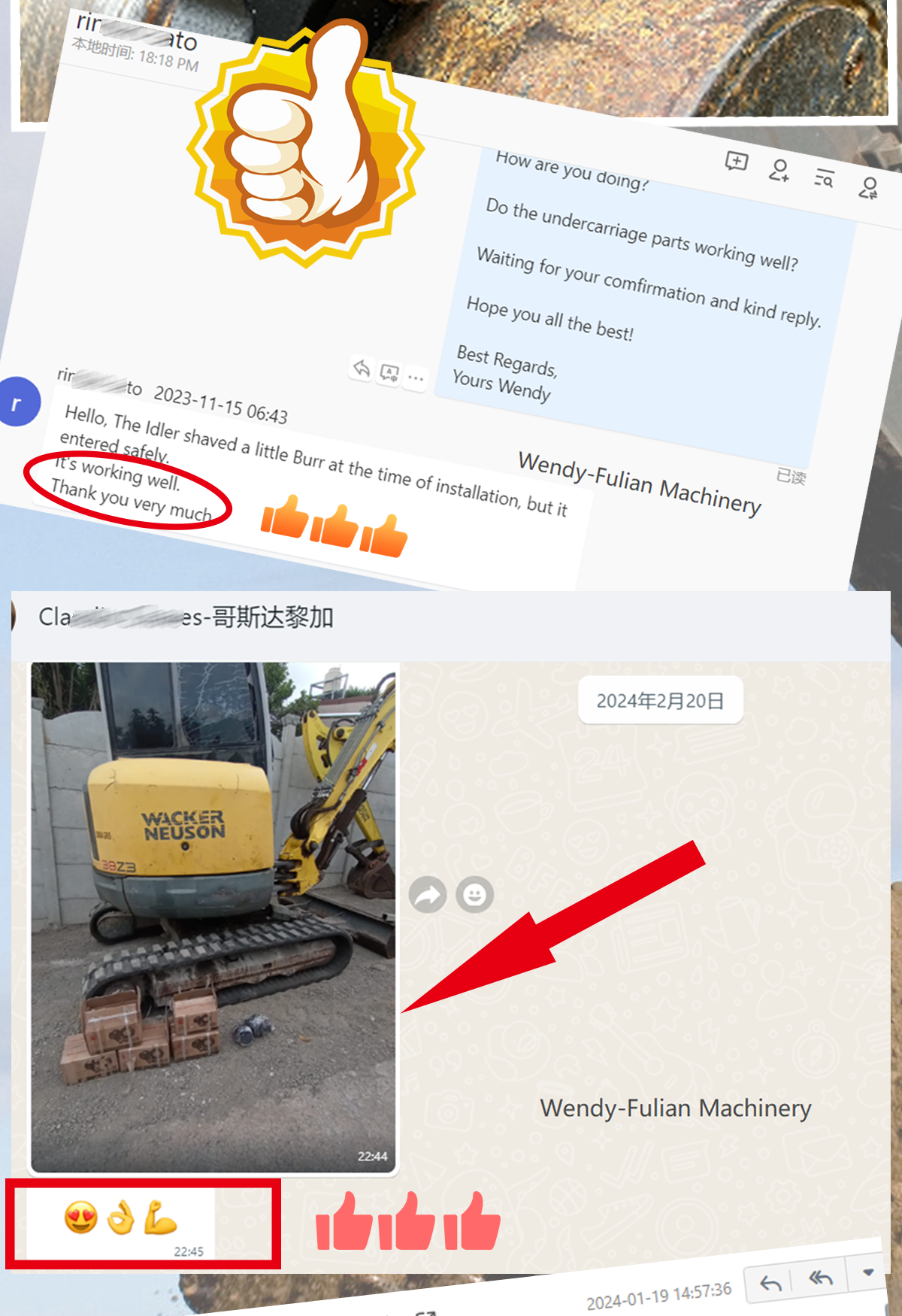

Customer reviews

Fulian Certifications

Packaging & Delivery

FAQ

What is a rubber track?

A rubber track is essentially a round belt made of a blend of rubber and either metal or fiber elements. It functions as a rubber transmission belt that is primarily used in moving systems. Owing to its durability and flexibility, it's a popular choice for agricultural machinery and construction equipment, serving as a viable alternative to traditional metal tracks and tires. The rubber track facilitates smooth transportation and enhances the efficiency of machines across various operational terrains.

Are rubber tracks better than steel?

When not utilized properly, rubber tracks are susceptible to damage from jagged or solid objects on the terrain. Navigating across slick or muddy conditions can prove challenging with rubber tracks. For such environments, a more resilient material like steel is a more suitable choice to ensure optimal performance and reduced wear and tear.

Why does my rubber track keep coming off?

A common cause for the derailment of a rubber track could be attributed to deformations in the track frame. A perfectly aligned and straight frame is paramount for the track's operation. With the passage of time and continual use, the track frame may suffer alterations such as twisting, bending, or incurring other forms of damage, which can impact the track's performance.

What are the benefits of rubber tracks?

Reduced ground impact: By evenly spreading the weight of the machine, rubber tracks minimize the likelihood of it becoming mired in soft ground. Enhanced operator experience: The supple nature of rubber tracks affords a gentler, quiver-free operation, contributing to a more agreeable day for the machine's operator.