Caterpillar (CAT) 301.4C 301.7D Sprocket (Fit Caterpillar (CAT) 301.4C 301.7D 301.7DCR Mini Excavator)

Basic Info.

- Item Fit: Caterpillar (CAT) 301.4C 301.7D 301.7DCR

- Item Condition: New

- Item Weight: 18 lbs

- Item Maker: FLundercarriage

- Place of Origin: Quanzhou

Delivery Info.

- Inventory Class: Standing

- Packaging: Carton/Pallet

- ETD: 24-72 Hours

- ETA: 5-30 Days

- Cat® 301.4C (Serial Numbers: LJK, LJ3)

- Cat® 301.7D (Serial Numbers: LJH, LJ4)

- Cat® 301.7DCR (Serial Numbers: LJ8, LJD)

- Teeth: 21

- Bolt Holes: 9

- Inside Diameter: 5 inches

- Outside Diameter: 12 1/4 inches

We advise inspecting and possibly replacing your rubber tracks and sprockets simultaneously. This practice promotes the maximum lifespan of your machine's undercarriage by ensuring these parts wear evenly.

- Caterpillar® Dealer Part Number: 381-3033

- Cat® 301.4C

- Cat® 301.7D

-

Cat® 301.7DCR

No alternate part listings have been identified. This sprocket (381-3033) is assured to be compatible with the above-listed models.

- Idlers for Cat® 301.4C

- Sprockets for Cat® 301.4C

- Bottom Rollers for Cat® 301.4C

201 in stock

Share This Product

Flundercarriage Show

Why Choose FL Undercarriage

-

20+ Years Experience

-

100+ Dealers Globally

-

300000+ stock Keeping units

-

50000000+ USD Annual sales

Product Range

Our sprockets are built to withstand extreme conditions, ensuring smooth and efficient power transmission in your machinery. Crafted from high-quality materials, they offer exceptional wear resistance and durability, making them ideal for heavy-duty applications. Trust our sprockets to enhance the performance and longevity of your equipment, keeping operations running smoothly.

Machinery brands our parts are suitable for Bobcat, Caterpillar, Case, Doosan, GEHL, Hitachi, Hyundai, IHI, Kubota, Kobelco, Komatsu, Pel-Job, Takeuchi, Volvo etc.

How are your sprockets produced

Trade Show Events

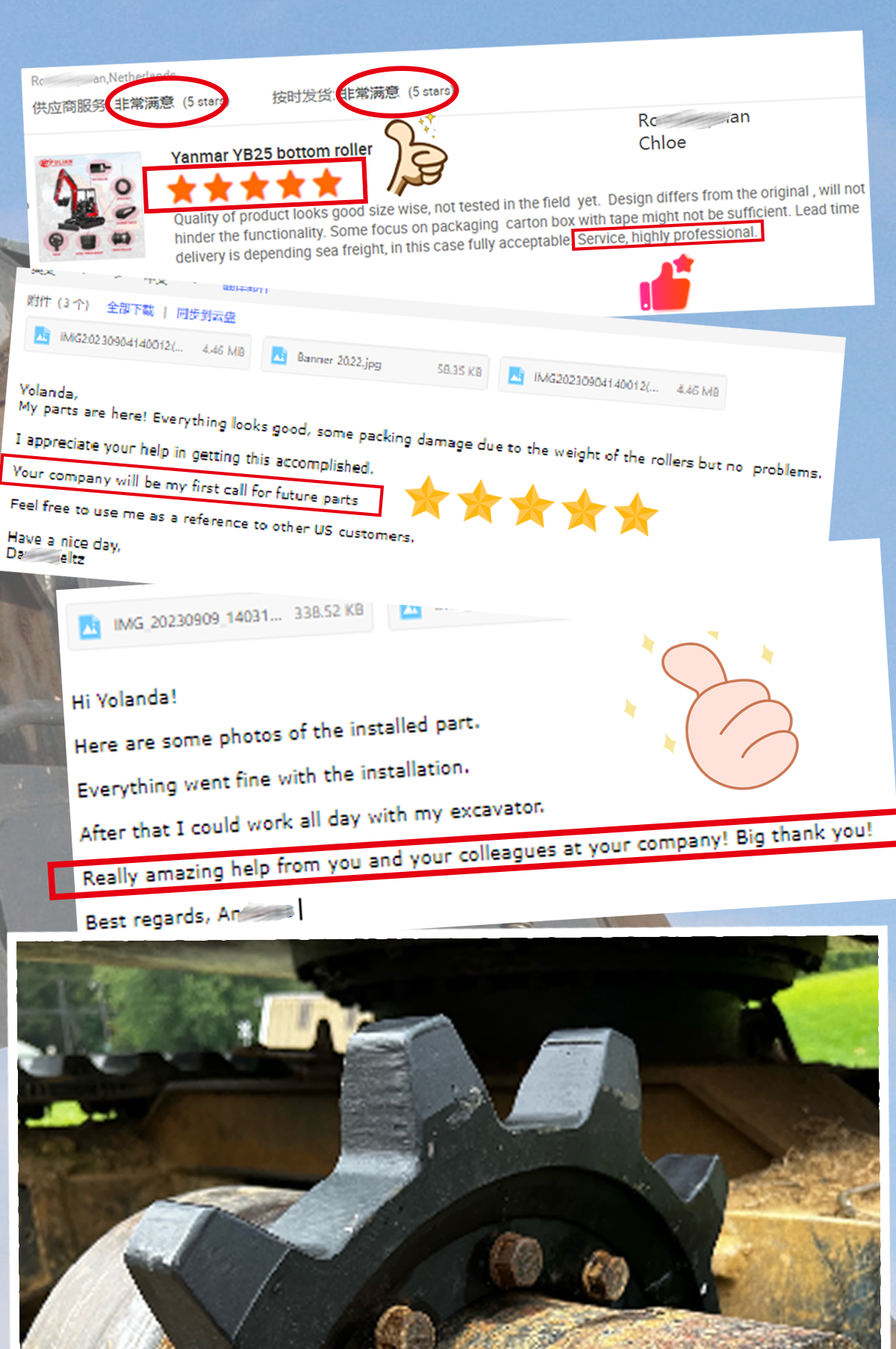

Customer reviews

FAQ

How often do excavator sprockets need to be changed?

A sharp gear indicates that the gear is worn. Check whether there are grooves around and under the gear that are similar to the chain shape. This "shadow" wear indicates that the gear has been seriously worn and should be replaced.

What are the contributing factors that lead to the deterioration of sprockets on an excavator?

Several factors lead to wear and tear of excavator sprockets, including:Heavy usage, Abrasive environments, Improper track tension, Inadequate maintenance, Rough operation, Quality of the sprockets, Misalignment of components, Age and metal fatigue

What maintenance routine can I follow to ensure my excavator sprockets last longer?

To extend the life of your excavator sprockets, implement a maintenance routine that includes:Regular cleaning of debris and dirt,Frequent inspections for wear,Ensuring correct track tension,Prompt replacement of worn parts,Lubrication to reduce friction,Using high-quality replacement sprockets,Operator training to prevent harsh handling.